Justin Smith

Established Member

On my N gauge layout my diesels run well, de-railing wise, but steam engines tend to be less reliable (particularly front bogie de-railing) and a Dapol A4 I have just bought is especially poor.

I have been doing a bit of research and it seems advisable to buy a "track gauge" (roller type ? ) and "back to back" wheel gauge.

A few of questions please !

Are these items worth getting ?

Are any particular types / models the best ?

If derailing occurs in the middle of points how can track gauge be checked with a roller type gauge and how can the gauge in the middle of a point be altered anyway ?

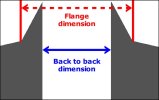

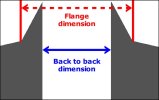

On the subject of "back to back" wheel gauges, surely their accuracy depends on the thickness and shape of the flanges ? How can the internal dimension "back to back" dimension be a reliable indicator of the more important distance between the flanges ? Plus it's not just about the thickness of the flanges its their shape, where does the rail head actually touch the flange ?

I have been doing a bit of research and it seems advisable to buy a "track gauge" (roller type ? ) and "back to back" wheel gauge.

A few of questions please !

Are these items worth getting ?

Are any particular types / models the best ?

If derailing occurs in the middle of points how can track gauge be checked with a roller type gauge and how can the gauge in the middle of a point be altered anyway ?

On the subject of "back to back" wheel gauges, surely their accuracy depends on the thickness and shape of the flanges ? How can the internal dimension "back to back" dimension be a reliable indicator of the more important distance between the flanges ? Plus it's not just about the thickness of the flanges its their shape, where does the rail head actually touch the flange ?