Nottingham59

Established Member

Tunnels shape a railway network for the next hundred years. Once built, they are fixed and the rest of the network has to evolve around them; their size limits the loading gauge of the line in perpetuity.

So where would you put them? This is the deal:

You are in charge of a fully-funded 25-year programme to build railway tunnels. You have three tunnel boring machines at your disposal: two always working and one being refurbished or replaced or being moved to the next site. There is a single central factory located near a source of limestone, sand and gravel, designed to produce 30 metres worth of concrete lining segments every day at absolutely minimum cost. There is an agreed spoil disposal point on the East Coast somewhere in Yorkshire or Norfolk where local residents welcome the dumped material as it replenishes shorelines and counteracts coastal erosion.

Each TBM can cut 14 metres per day, or 5km per year. So after 25 years that's a total of 250km of tunnel. Don't worry about matching the TBMs to the geology, e.g wet shale under a river versus hard rock versus chalk. Assume you can do all the tunnels with a similar geology together, and then re-configure or switch machine types for next batch. They're going to wear out well before the 25 years are up!

The TBMs are HS2-sized, which is 8.8m internal diameter. This is big enough to accommodate:

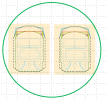

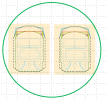

In the first diagram, the purple outline is UIC-GC gauge, used for HS2 trains. In the second, the inner green outline is for GB passenger trains, the brown flat-topped profile is W12 freight gauge. (Remember that you can't normally mix speeds. The cant required for a TGV at maximum curvature means that a slow-moving freight would slide to the side of the track and cause excessive wear.)

So where would you put the tunnels? And where, precisely, will the portals be? You can have plain tunnel, and perhaps underground junctions.

(But no excavated stations; building stations underground is massively expensive and would distort the economic premise of the thread, which is that the tunnelling work might cost £33m/km at 2015 prices, so your civil engineering budget is £330m per year. Other budgets will cover fit out, and rolling stock etc. For more information about tunnelling and costs, see the HS2 guide: https://www.gov.uk/government/publications/hs2-guide-to-tunnelling-costs).

EDIT 30/06/22: Bald Rick, who know about these things, says that the HS2 Guide shows prices as of 2011, and that current prices for just building a tunnel without fit out are now around £100M/km. So your tunnelling budget is now £1Bn per year. Use it well.

So where would you put them? This is the deal:

You are in charge of a fully-funded 25-year programme to build railway tunnels. You have three tunnel boring machines at your disposal: two always working and one being refurbished or replaced or being moved to the next site. There is a single central factory located near a source of limestone, sand and gravel, designed to produce 30 metres worth of concrete lining segments every day at absolutely minimum cost. There is an agreed spoil disposal point on the East Coast somewhere in Yorkshire or Norfolk where local residents welcome the dumped material as it replenishes shorelines and counteracts coastal erosion.

Each TBM can cut 14 metres per day, or 5km per year. So after 25 years that's a total of 250km of tunnel. Don't worry about matching the TBMs to the geology, e.g wet shale under a river versus hard rock versus chalk. Assume you can do all the tunnels with a similar geology together, and then re-configure or switch machine types for next batch. They're going to wear out well before the 25 years are up!

The TBMs are HS2-sized, which is 8.8m internal diameter. This is big enough to accommodate:

- 1 track of HS2-style railway, at 300-400km/h. (For these speeds assume the minimum radius of curvature is 5000m, and the maximum gradient of 3%.)

- 2 tracks of conventional GB railway, with passenger trains at 110mph. (Assume 1500m curves and 2% gradient)

- 2 tracks of conventional GB railway, with W12-gauge intermodal freights at 75mph. (1000m and 1%)

- And you could in theory fit four London Underground tube lines into the space, if you wanted to.

In the first diagram, the purple outline is UIC-GC gauge, used for HS2 trains. In the second, the inner green outline is for GB passenger trains, the brown flat-topped profile is W12 freight gauge. (Remember that you can't normally mix speeds. The cant required for a TGV at maximum curvature means that a slow-moving freight would slide to the side of the track and cause excessive wear.)

So where would you put the tunnels? And where, precisely, will the portals be? You can have plain tunnel, and perhaps underground junctions.

(But no excavated stations; building stations underground is massively expensive and would distort the economic premise of the thread, which is that the tunnelling work might cost £33m/km at 2015 prices, so your civil engineering budget is £330m per year. Other budgets will cover fit out, and rolling stock etc. For more information about tunnelling and costs, see the HS2 guide: https://www.gov.uk/government/publications/hs2-guide-to-tunnelling-costs).

EDIT 30/06/22: Bald Rick, who know about these things, says that the HS2 Guide shows prices as of 2011, and that current prices for just building a tunnel without fit out are now around £100M/km. So your tunnelling budget is now £1Bn per year. Use it well.

Last edited: